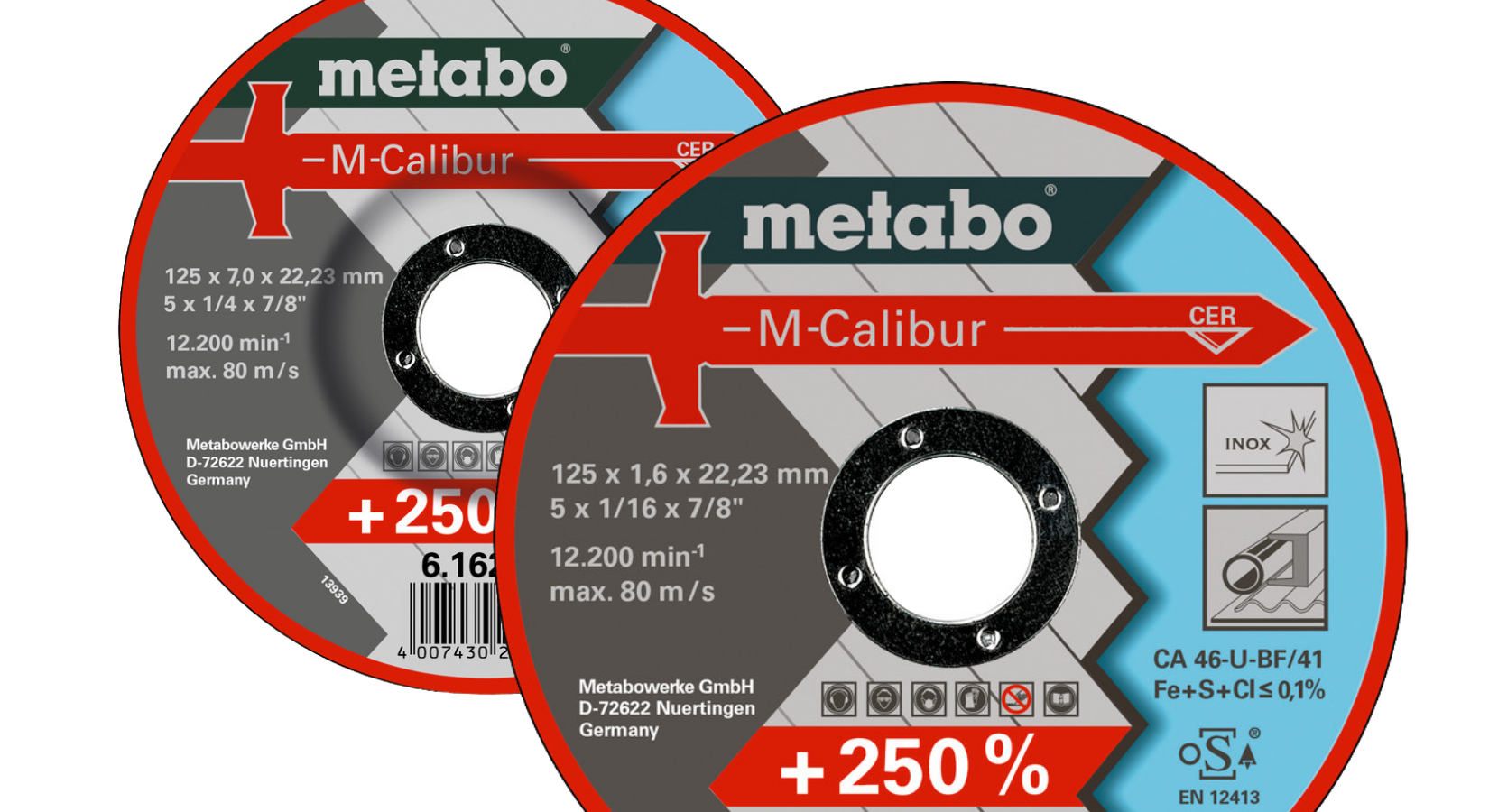

“M-Calibur” Cutting and Grinding Discs

Metabo Experience

Metabo have been manufacturing professional grade tools for some 100 years now and continue to lead the industry in product development, highlighted once again by their recent release of the world’s first 1700 watt compact angle grinder.

Just like a Formula 1 car relies on quality tyres to perform at its peak, all powerful machines are only as good as the accessories they use to deliver the performance they are capable of.

Metabo first began developing their own range of grinding accessories over 60 years ago, longer than any other tool manufacturer in the world, and they continue to apply their knowledge and experience to new product technology ensuring professional users have the right accessories for their tools to perform at their highest level.

The Technology

Being cost-effective and suited to a wide range of materials and applications, Aluminium Oxide has long been the most popular abrasive grain for metal processing.

Aluminium Oxide grains do, however, wear down during use which decreases their effectiveness over time.

“Ceramic grain” technology was since developed where, through a sintering process, Aluminium Oxide grains are transformed into a grain that “micro-fractures” rather than wearing down.

This fracturing continually exposes new sharp, cutting edges to deliver peak performance which is maintained throughout the life of the disc.

The "M-Calibur" Difference

Whilst the effectiveness of an abrasive grain is important, the significant improvements in cutting and grinding disc performance today are based more around “bond” technology.

Metabo's "M-Calibur" range uses a unique bonding formula that holds the abrasive grains in place as long as possible to maximise the performance of each individual grain before it is released.

This has been the key to success of the “M-Calibur” range of cutting and grinding discs, which have been proven to deliver unequalled performance, productivity and longevity.

While many manufacturers focus on either performance or tool life, Metabo have used the opportunity to address both sides of the equation in the development of the “M-Calibur” range.

By combining advanced ceramic grain abrasive technology with a unique bonding process focussed on longevity, the “M-Calibur” range delivers an unequalled combination of performance, productivity and longevity.

Proven Performance

In testing against other high-performance products, “M-Calibur” grinding discs consistently achieved up to 3 times the rate of material removal, while the cutting discs produced over 250% more cuts per disc in the same time as standard wheels of many well known competitors.

These results not only highlight the obvious performance increases, but also the unequalled cost savings made possible through increased disc life and a significant overall reduction in labour costs.

Applications

Contaminant free and suitable for use on steel, stainless steel and non-ferrous metals, these high-speed performance discs are perfectly suited to the most powerful angle grinders.

High lateral stability and super fast cutting performance is delivered without compromise on safety, which is always a priority at Metabo, with the range exceeding the requirements of all relevant safety standards (EN 12413 and OSA).

Try "M-Calibur" Today

The full range of Metabo “M-Calibur” cutting and grinding discs is available in Australia through TSPC - The Surface Preparation Company. Visit us at surfaceprepco.com